No matter which industry you belong to, manufacturing is always the backbone. Profit lies in the creation. The raw materials you take in, creative workers you hire and machines you buy decide how much you’re going to take home.

The fourth industrial revolution has got everything under its huge umbrella; manufacturing is not untouched. The wave of revolution is meant to bring automation, the Internet of things, and Artificial Intelligence into manufacturing. It’s already happening as factories are lathered with automated machines to perform tasks — basic or complex- with perfection.

In this scenario, if you buy an already established business, it’s better to plan the involvement of advanced tech. While you wait for a business valuation or appraisal, you can work towards hiring talent who understand the trends in manufacture. Better yet, you yourself can start learning about them.

How does the fourth industrial revolution change the manufacturing industry?

Industry 4.0 is here and smart factories are the need of the hour. Smart factories are ones that are run by software systems with real-time communication and automated operations. This reduces the chances of human error and cuts the cost of paying employees for basic tasks.

Many jobs in the factories will be taken over by machines but not all. At Ford, co-bots or collaborative robots are working hand in hand with workers to finish mundane or heavy load tasks so that humans can do more mental work.

Top Trends in the Manufacturing Industry?

1. Virtual Manufacturing

Getting the model absolutely right on the first try seems to be mere luck. But with virtual manufacturing, this will be the new normal. Designers will perfect a model on software before physically creating it. The near animated process promises sure shot results which save time, money, and room for error. Manufacturers will be able to launch products faster than ever.

Boeing, an aerospace company, is using Google Glass and Skylight software to provide insights on complicated wiring. No doubt many companies will be adopting this fresh method very soon.

2. Micro Manufacturing and Error Detection

All machines that people use in general are meant to be portable and lightweight. Thus, they need micro-components to be fitted inside them to function marvelously. Mobiles that we use on a daily basis are built from a network of these micro components. This technology is widely used in the field of medical science to create micro machines.

Another trend in error detection is fixing remaining loopholes in the mechanism of creation. In smart factories, all machines will be connected to AI which will communicate in real-time. This allows them to detect and solve problems themselves. They are capable of halting the tasks that seem faulty to prevent wastage in the future.

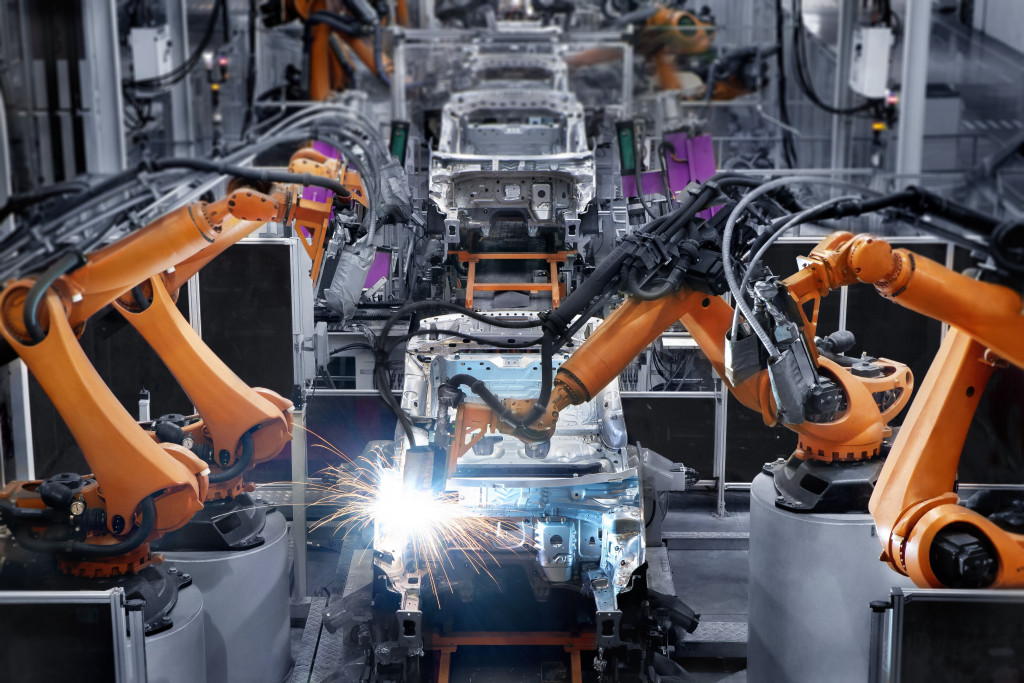

3. Robots

The fourth industrial revolution is riding on the back of robots. They’re here and there’s no denying it. Whether they’ll end humanity or not — nobody knows — but for now, they are proving to be very useful to humans. Many companies, especially automobile ones, are hoarding robots to work in their manufacturing sector.

There are all kinds of robots and not all of them eat up human jobs. General Motors are all set to use robot gloves which are to be worn by their workers. They are meant to reduce strain on hands and help them lift heavy objects easily. More and more robots are being used in factories that work with humans and not for them.

4. Sensors and sustainability

When everything is being automated, there is bound to be human supervision. Machines can’t replace us that fast. Sensors are placed on all equipment to track their work. Data about industrial usage is updated on smart devices, where it is analyzed and checked for error. Another advancement is sustainability.

Humans are far too close to destruction. We just can’t afford industrial waste anymore. Therefore, robots are placed to recycle and safely dispose of this waste. Daisy, a smart robot used by Apple, removes useless parts from old iPhones and recycles them for reuse. This allows the brand to avoid charges for new parts as the robots automatically fix the old ones.

5. 3D Printing

It’s not short of magic. 3D printing has revolutionized manufacturing. The sophisticated technology simplifies manufacturing which benefits both users and companies. 3D printing works with the help of Computer-Aided Design (CAD). The task is to create 3D objects from a wide range of materials available. This technology is not fully developed as of now and is still in the testing phase.

If you’re starting a business in manufacturing, you must consider incorporating some of these techniques in your factories. They might cost you some extra money but will save a lot in the long run. Any company that wants to stay relevant in the coming years must invest in these technologies. There’s no way around this. A business that lacks these innovations will certainly die down.